Why Choose a Tower Farm?

Amazing Value

Start up cost @ $118 p/tower with 28 plant sites p/sqm. Scale up to 60 plant sites p/sqm (Ask us how).

Amazing results

Expect robust, healty growth & commercial quality produce. See below video for what crops grow best in tower farms.

Hydroponic or Organic Nutrients

With hydroponic fertigation we inject superior blend nutrient into the water flow. With Organic, we add pelletized nutrient to the medium then add normal water.

Smart Technology capable

Choose the 'commercial fittings' option above for Wifi controlled irrigation from your phone. In-line EC/PH/Temp metering solutions also available etc.

Outdoor or Greenhouse

The Coco/perlite medium is an effective buffer against temperature variance enabling successful growth in various climates. See our outdoor overhead netting solutions or greenhouse & poly tunnel packages

Water Efficient

Tower farms can use up to 98% less water than traditional farming methods. Every drop of water is delivered directly where it is needed.

Energy Efficient & Off Grid capable

Each tower requires only a small flush of water 3 times p/day. Compare that to aeroponics or NFT where constant recirculation is needed and the energy saving is massive! Solar options also available.

Quality Service

Dedicated Australian office with phone support and expert assistance. Detailed installation instructions included or we can set-up the whole farm for you.

Best Crops for Tower Farms

General Info

A Conservative Business Case

100 Tower Parsely, Basil, Coriander, Mint Farm

- 100 meter area (10 x 10)

- 4 plant sites p/stack, 7 stacks p/tower = 2800 total plant sites

- 2 bunches p/plant site p/month = 5600 bunches

- 5600 bunches @$1.50 p/bunch = $8,400 gross sales p/month

- $8,400 p/month x 12 = $100,800 p/year

- Upfront investment $10500

- On-going costs approx $7000 p/year

(nutrient + water + coco coir + packaging) - Net income p/year $80,600

Note: Yield increases exponentially as you stack higher!

Commercial Farming FAQ

We recommend min 1 to 1.2 meters apart to ensure adequate sun to all sections of the farm.

This is an excellent method to increase sunlight to the lower parts of the tower. In fact out latest recommended design for commercial set-ups is 3 meter poles that are secured overhead with simple wiring. Then a planter at the base of the tower, then first tier 500mm above the ground, then 5 medium stacks, then 25mm spacer, than 5 medium stacks. See this picture for an example

- Commercial quality yields (vertical growing methods)

- No waste product or flushing of system required

- Low operational costs

- Plant constantly receives fresh nutrient instead of reconstituted/depleted nutrient

- Easier to maintain a consistent PH level

- Nutrient water is less prone to pathogen attack

- Significantly less logistical and maintenance issues compared to re-circulation

- Effective insulation of roots from extreme heat (using coco/perlite medium)

- Strong buffers against any prolonged moisture loss

- Almost no electricity usage as there is no water pump required

- Highly cost effective with reusable medium

This depends on a range of factors including sunlight, temperture, plant types and phases etc, but as a rule, we recommend budgeting for 1 litre per tower per day.

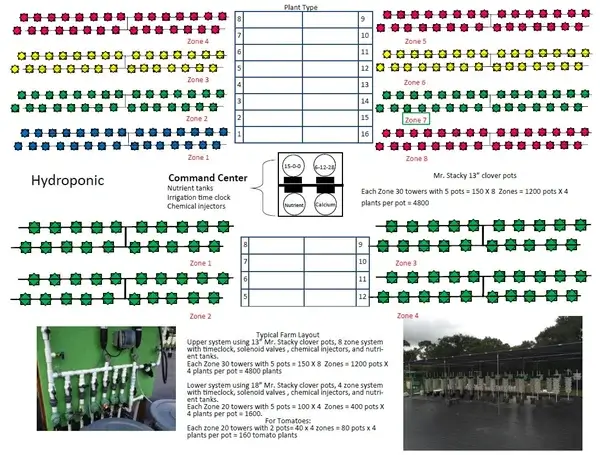

Vertical farming with hydroponic technologies are expanding rapidly all across the world due to increased urban farming demands and production needs.

Most hydroponic facilties carry a substantial infrastructure outlay with the need for greenhousing, water re-circulate, water, temperature and pest management, reservoirs, pumping etc etc.

The infrastructure cost of a Mr Stacky tower farm are significantly less other systems with arguably an even better yield per square meter. With our latest farming methods, we have simple and scalable solutions for pest management, crop rotation, sunlight optimization, wind management and even an innovative per tower mini greenhouse solutions.

With a recirculating farm (eg. NFT), you run the risk of water born diseases being carried through to the entire farm. Our tower farms use a fertigation method which ensures fresh clean nutrient every feed with almost no water management overheads or expensive monitorring systems.

Our injectors are high quality with 1 year warranty and come with replacement parts to maintain optimal useage over time. They are used in commercial fertigation set-ups all over the world. They work like a venturi. As water is pushed through (from water pressure), a suction action is created inside the device, which extracts liquid fertilizer from a reservoir below and injects this into the flow of water which goes out to the garden. It is adjustable so you can varry the output from 0.4% – 4.0%

Fertilizer Injector FAQ's

No, it’s actually very easy. Just install it against a wall between the garden and your water mains or water tank. The hardest bit is ensuring the right EC to your garden. We show you exactly how to do this. See this video

These devices have been used in large scale agriculture & farming practices for decades. They are powered by water pressure. As water enters through the inlet, it drives an internal suction action just like a toilet plunger. This creates a vaccuum within the device which draws nutrient upwards from a tank below and injects this into the water flow at quantities between 0.4% to 4% of the total flow.

- No electricity needed

- No pumps needed (if using water mains)

- No reservoirs needed

- Injects fresh nutrient every feed

- No recirculation needed

- Long lasting, commercial quality

- Allows precise nutrient measurement

- Automated & easy to maintain

This set-up is best used for larger scale operations which are cycling through more than 100 litres of water per week. It means you spend less time managing your reservoir. Because they rely on water pressure, they’re much more scalable then a water pump. 2 injectors are sufficient to power an entire 100 tower farm. (Part A & Part B nutrient)

They come with a 1 year warranty on malfunction or parts replacement. They also come with replacement seals which can be used after 1 year or so to extend the life of the device well past 2-5 years.

Basically, this is a high quality venturi. You can pickup small venturi devices for $20 but in our experience they don’t work! It’s very hard to regulate the amount of suction and you end up wasting heaps of nutrient. Also, the venturi’s we’ve tested are very tepremental. It might work ok for a day, and then it stops sucking properly and your constantly second guessing if it’s working! These injectors are made for commericial growers who need consistency and longevitiy. Yes, the cost more, but they’re worth it.

Typically, the main issue is build up of mineral salt in the 6mm hose which extends into your nutrient solution. This can be easily resolved cleaning the hose fortnightly with a wire or simply running clean water through it.

For commercial farms, we recommend 2 x injectors. 1 for Part A & 1 for Part B. However for smaller residential set-ups, simply use 1 injector and combing the Part A & B nutrient in one reservoir at an EC of 15. This ensures no significant nutrient ‘lock-out’ or detrimental results. See these results. (All based on 1 injector and combined Part A &B at EC15)

Hydroponic Nutrient FAQ's

There is much conjecture about the nature of hydroponic nutrients and their safety in comparison to ‘natural’ or ‘organic’ soil. See this article for detailed info.

The artical concludes that:

a) Hydroponic nutrients are derived from the same base materials that conventional soil based nutrients are made

b) There is no evidence to support that plants grown with hydroponic mineral salts are detrimental to human health in any way. This evidence is based on multi-decades of analysis and use worldwide.

All plants need fertilizer to grow. In traditional gardening plants receive nutrient from the soil which is enriched with minerals and organic additives which may include manure & compost. These soil additives can be very effective, but as with many ‘organic’ products, there is the potential for large disparity in the actual contents.

Nutients can be categorized as follows:

1) Macronutrients. Plants need these in large amounts. This includes: Hydrogen, Carbon, Nitrogen, Oyxgen, Phosphorus, Calcium.

2) Micronutrinets. Plats need these in small amounts>

This includes: Zinc, copper, iron, manganese, boron, cholorine, nickel, molybdenum, nickel.

Standard hydroponic nutrients are derived from mineral salts. Hydroponic nutrients are simply plant nutrients that are designed for use in a hydroponic system. Plants require 16 elements to grow. Carbon, Hydrogen, Oxygen, and Nitrogen are already available in the air and water that they are receiving.

Mr Stacky Australia

Varsity Lakes, QLD 4227

ABN 802 266 459 01

(2x, 3x, 10x with every 100 Towers!)

(2x, 3x, 10x with every 100 Towers!)

Some project ideas we had: purchase a freeze dryer so there is no food wastage, distribution models to sell the food, community project focussing on food security solutions for the Gold Coast, sponsoring Mr Stacky vertical farms to be set up in other suburbs, building a community of volunteers, study herbalism, grow the plants and create tinctures to be used as natural medicines and teach others, cooking classes to make jams, preserves, recipes from the food we grow, healthy eating and gardening school programs.

Update 2022: After success inititally we decided to switch from the organic nutrient to the hydroponic nutrient as we had a very wet season and found the nutrient was being washed away faster than the plants could absorb it. Since we’ve switched to the hydroponic nutrient, the plants have made a massive improvement and we’re looking forward to the next picking season!

As we get alot of wind on the island, we’ve used wind netting around the garden. This also creates a physical barrier for wildlife and a gating structure for customers. We’ve also constructed meshing above the towers to stop birds as well. In addition to strawberries we’ve succesfully grown various crop types including snowpeas, beetroot, brocoli, radish, cabbage etc. We’re targeting an open date prior to Christmas (depending on the COVID19 restrictions)…